The Applied Compression Advantage.

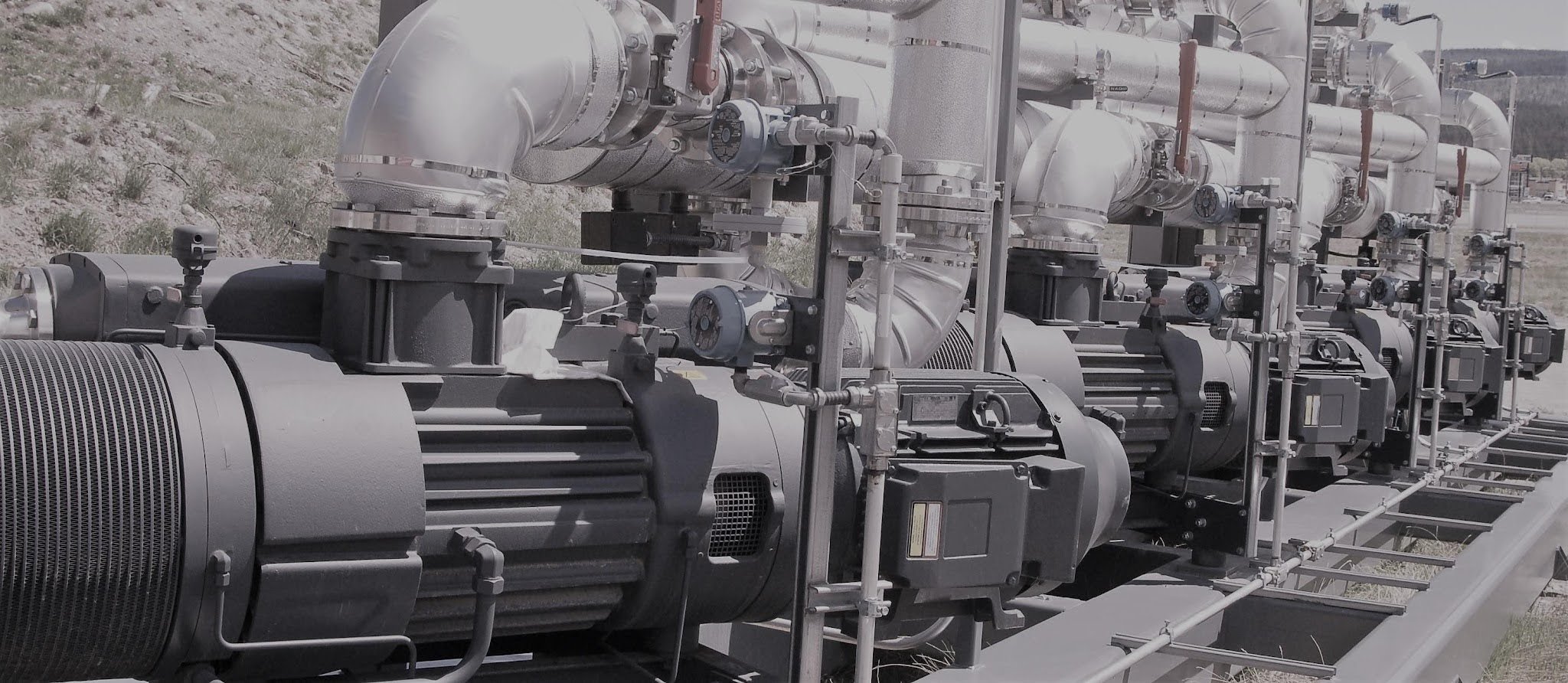

Your single source solution for any low-to-mid range horsepower specialty gas and air compressor packaging requirements

What is the Applied Compression Advantage?

Applied Compression Systems Ltd. is a leading provider of custom-designed and fabricated compression systems for various industries. Our natural gas compressors and other gas compression packages are engineered to meet the highest standards of efficiency, reliability, and durability.

As a vertically integrated company with decades of experience, we offer several key advantages:

Reduced Construction Costs: Our shop costs are much lower than those of field construction.

Single Source Responsibility: From concept to solution, we provide design, engineering, fabrication, and testing.

Guaranteed Component Compatibility: One source for all the major components, ensuring component compatibility and process functionality throughout the entire system.

Reduced Lead Times: Many of the standard packages that we offer are pre-designed for quick turnarounds.

Flexible Design: Our flexible modular design allows us to plan and fabricate a compressor package to meet individual customer specifications and industry specific applications quickly and economically.

What you can expect when you choose Applied Compression for your project?

Personalized Attention: ACS offers a personalized approach, taking the time to understand your specific needs and requirements.

Flexibility: We pride ourselves in being flexible and work closely with clients to deliver a solution that meets your unique needs.

Agility: We like to think we are nimble and quick to adapt to changes and can respond efficiently to urgent client requests.

Innovative Solutions: Providing innovative solutions custom-tailored to our clients’ needs is what we do every day.

High-Quality Craftsmanship: We have a strong focus on quality, as we appreciate repeat business and referrals.

Tailored Expertise: We have developed a deep understanding of industrial compressors and their applications across diverse industries. We specialize in industrial compressors for various applications.

Collaboration Opportunities: We value collaboration and enjoy working closely with our clients throughout the design and fabrication process. This collaboration strengthens our partnership with clients, fostering creativity and innovation.

The Applied Compression Commitment.

At Applied Compression Systems our mission is clear: empower our clients in harnessing the potential of their projects – whether for RNG, Biogas, Hydrogen, Natural Gas or Research of New Technologies – to foster sustainability and energy resilience for generations to come.

We are committed to:

Enhancing Sustainability by assisting our clients in repurposing waste through energy recycling.

Empowering Clients to fulfill their clean energy projects while enhancing their environmental stewardship.

Amplifying the Impact of RNG/Biogas by collaborating with our clients to bring their project opportunities from concept through to completion.

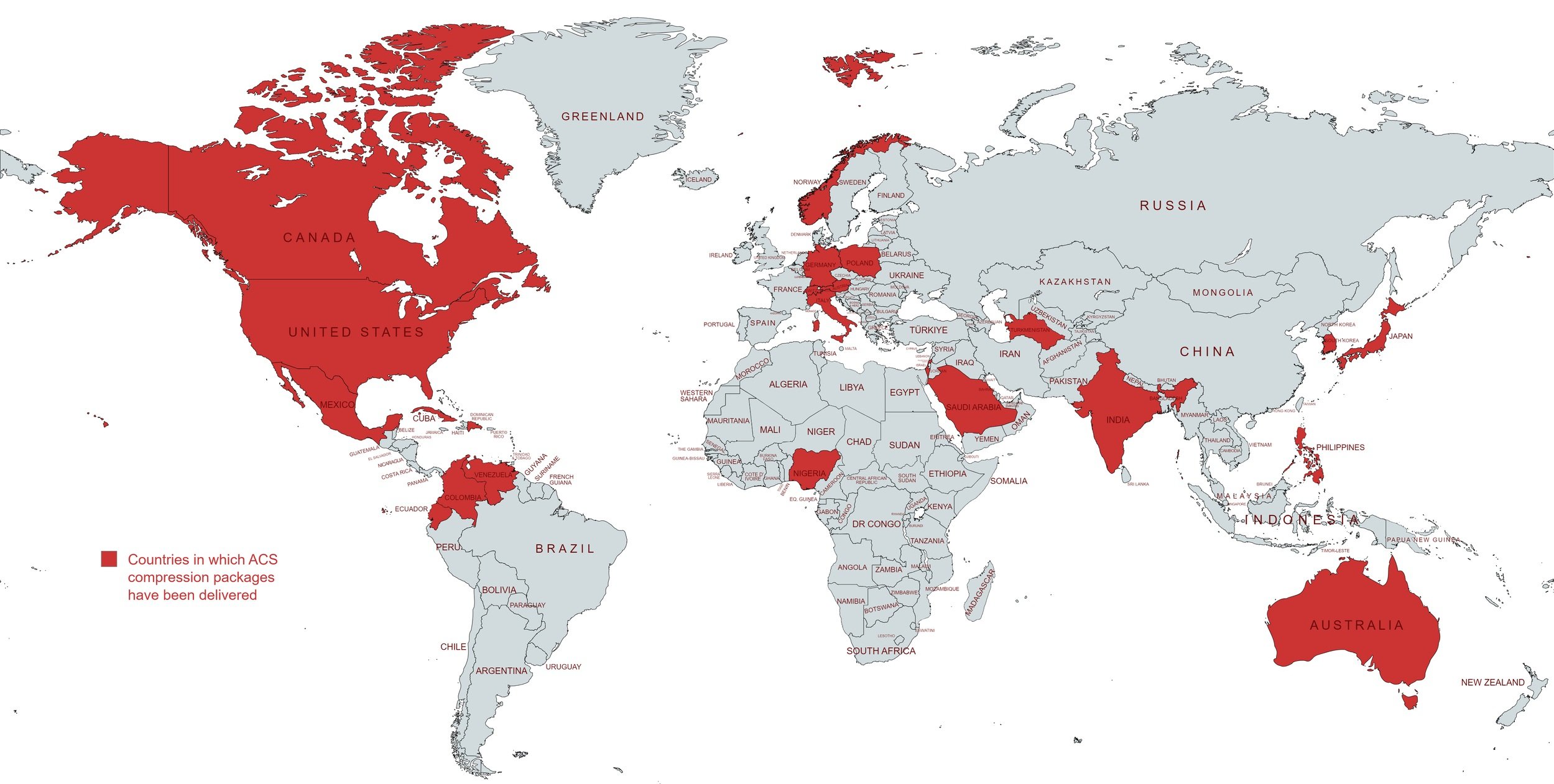

Custom compression packages installed worldwide since 2011

800+

Talented team members providing innovative solutions custom-tailored to our client's needs

30+

Sq. ft. of space dedicated to design, fabrication, custom controls, testing and quality assurance

15k+

Over 800 custom-engineered compression packages delivered and installed worldwide to meet our clients' specific requirements for air compressors, gas compressors, industrial applications, oil and gas, mining, power generation, research and development, and more.

Recent News

Your project can't wait for a custom package to be built? Inquire with our sister company, Canadian Purcell Machinery Ltd., about high-quality used compression equipment that is ready to ship today!